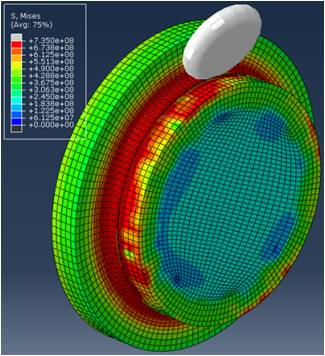

Numerical Simulation of Fabrication Processes

The progress of both computer hardware and numerical models capable of accurately representing complex phenomena has allowed the use of numerical simulations to investigate fabrication processes such as hot forging, cold stamping, welding, rolling and manufacture of advanced composites. Commercial FE packages are constantly improving and building knowledge and capabilities to perform intricate numerical simulations. However, huge challenges remain unanswered and there are great opportunities to develop state of the art research in numerical simulation of fabrication processes.Advanced Composite Materials

The need of lightweight, good strength characteristics and resistance to thermal

effects in areas such as aircraft design, robotics, automobile industry and smart

control have increased interest in composite materials. The design of composite

structures is complicated by the wide variety of available matrix and fiber

reinforcement materials, the potential of stress concentrations, thermal residual

stresses from the manufacturing process, the choice of ply thicknesses and number

of plies and the spatial variation of ply orientation. Therefore, design and

optimization of composite structures involve elaborate models and procedures that

must be improved through further research and investigation.

Optimization

New techniques to optimize aerospace structural components shall be proposed that can

handle the multiplicity of load cases typically involved in practical designs. Innovative

optimization problems must be posed that lead to robust optimal designs in the sense

that they are able to withstand all the possible load cases applied to the structure.

The new techniques ought to be efficient from a computational point of view in order to

avoid optimization problems so large that they cannot be solved

by the algorithms currently available. The object of this project is to develop a

design procedure that results in structures optimized against arbitrary loads. This

general procedure is based on a minimax optimization strategy where the design

variables are geometric parameters and/or ply orientation of composite

structures while the uncertain loads are represented by parameters that describe a

family of piecewise linear loadings. The loading discretization enables one to treat

arbitrary boundary conditions and loads.

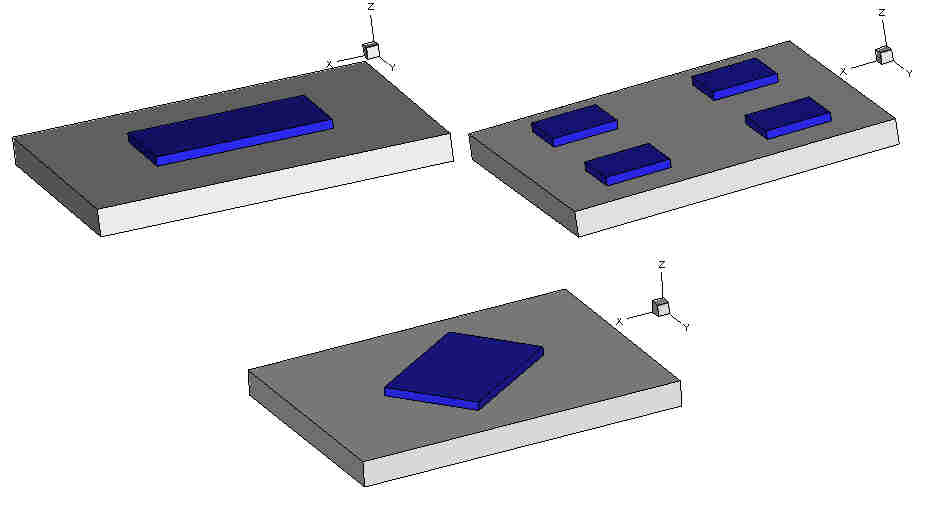

Smart Structures

Piezoceramics and their applications in active and shape control of isotropic and

composite structures are the subject of intensive research. It has been shown that

piezoceramics can be effectivelly used as actuators/sensors in the control of

structures. Their lightweight, relatively low cost, small size and good frequency

response make them an attractive alternative to conventional point actuators commonly

used in shape control and noise suppresion. New applications of piezoelectric materials

such as prebuckling enhancement, cylindrical shell actuation, and stiffening effects

require the formulation of accurate models that need to be sharpened in order to

predict structural responses more precisely.